There’s more to your cup of ceremonial cacao than the act of making it from your chosen block or bar of cacao. The journey from the rainforests of Bali is part of the ceremony; you aren’t just consuming a drink, you are a participant in this journey.

Cacao in the rainforests

Like any ecosystem, a rainforest is balance of give and take between the wildlife. Cacao trees were originally native to the jungles of South America and now occupy a similar niche in the Balinese rainforests. They are semi-wild; left to themselves they fit effortlessly into the landscape as they are relatively small “understory” trees. With some thoughtful attention they can produce reliable crops without threatening the forest around them.

Paying too little attention to the trees doesn’t help anyone – there is too little cacao, too difficult to harvest and process, to sustain even a modest business. Trying too hard gives short-term business gains but undermines the forest on which the cacao tree relies. Going all the way to create dedicated cacao plantations maximises yield, maximises profits for large corporations but trashes the environment and gives standard, uninteresting cacao. The journey to your cup started with years of hard work to create a sustainable balance of business, rainforest and richness of flavour.

While there are traditionally 3 varieties of cacao (Criollo, Forastero, and, in this case, Trinitario), once you add in sub-varieties and the influence of “terroir” – the combination of sun, shade, rain, minerals, temperatures, the flavours that emerge from the beans are part of the ceremonial journey.

The cacao flowers grow on the trunk of the tree so, after pollination (by tiny flies) the pods grow on the trunks before ripening then harvesting with a sharp machete or (higher up) a desgarretader, a sharp blade on a long handle, that damages neither the trunk nor the pod.

From the tree’s point of view, the pods exist to fall off, break open and attract whatever animals will relish the sweet white pulp, eat the tough seeds and, hopefully, deposit them later with extra fertilizer to start a new tree. The seeds are bitter, to discourage animals from biting them open.

From our point of view, we want to break open the pods as soon as possible, remove the beans, wet with pulp (and maybe make some delicious drinks from the remaining white pulp) and recycle the husk and the internal spine that had been holding the seeds. The seeds, which from now on we’ll call beans, are not yet fit for their onward journey because, as noted above, they are bitter & astringent. If you just dried and roasted them, the results would be entirely uninteresting.

What we therefore want is a natural process that transforms some of the bitterness and creates new (proto) flavour molecules. “Proto” because after fermentation, the flavour of a bean is still unpleasant. The transformation from proto to real is described later.

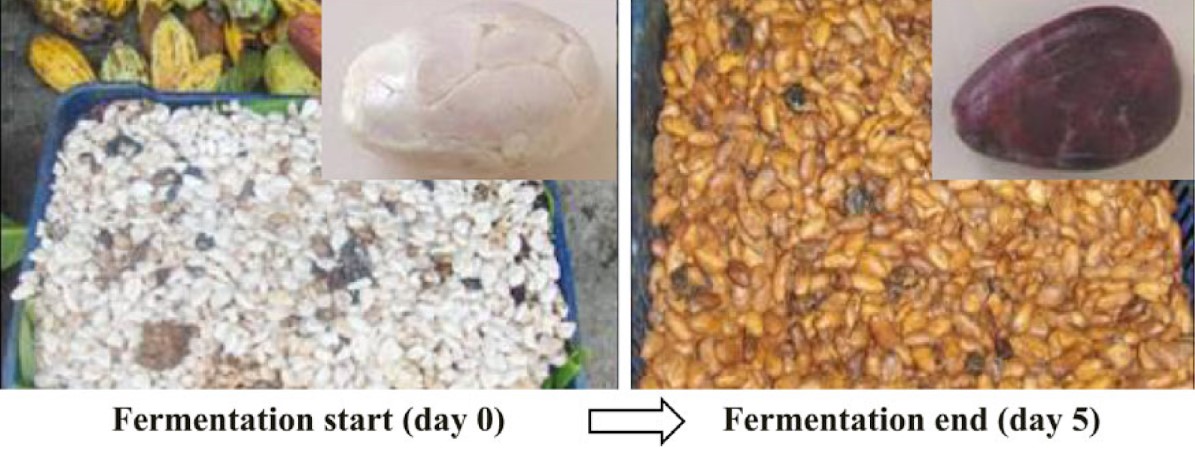

Fermentation starts by natural bacteria and yeasts feasting on the sugars in the remaining pulp. Because there is plenty of oxygen, although there is a strong burst of alcohols produced at the start the fermentation produces lots of acetic acid, with it characteristic “vinegar” smell and plenty of bitter lactic acid. We will see that getting rid of the acetic acid is a key part of the journey, but for now the acids are vital as they break down some of the chemicals inside the beans, especially the phenolic antioxidants that make the beans so inedible. There are plenty of other processes affecting proteins, sugars, colour molecules. Breaking down cell walls releases enzymes that also break up chemicals such as the complex phenols.

The fermentation produces a lot of heat. Controlling the temperature during fermentation is important. Too cold and the desired changes don’t take place. Allowed to get too hot can over-do some of the chemistry and kill off the fermenting organisms. Typically we want ~ 50°C.

To keep the fermenting beans under control they tend to be spread on open mats that allow excess liquids to drain away, provide access to oxygen, while covered by, say, banana leaves to keep them warm, sheltered from the rain and away from pests. As fermentation takes several days, the beans need to be turned regularly to ensure the process is uniform.

Just because something is natural doesn’t make it good. There is a natural “microbial succession” where yeasts give way to acid bacteria (good) which give way to spore formers (marginal to bad) then to molds (bad!). If these molds join the feast, they can impart some seriously bad flavours. So fermentation requires skill and knowledge. Relying on a few individuals who have the “feel” of fermentation is fine, but has its limitations. The other extreme of attempting to automate and mechanise is neither practical nor desirable for high quality cacao. The happy medium is to use modern low-cost sensors to monitor key factors such as temperature, acidity and oxygen to give early warning of problems that might otherwise have trashed a whole, precious batch. Another key is controlling the physical environment of the covered trays.

Trays spread out over a large area are picturesque but undesirably exposed to risks such as being too close to traffic. Trays arranged in modern industrial buildings are super efficient, yet this is both costly and unsightly. Finding a happy medium (e.g. relatively simple buildings that allow smart stacking of the trays) is another part of the long journey.

Drying

We need to stop the fermentation process (i.e. kill off all the microorganisms) and to remove the large amount of water (~40%) in the fermented beans (plus some of the volatile acetic acid). This could be done with lots of energy and mechanisation but with access to plenty of sunshine, the beans are spread out in layers as thin as possible with as much air flow as possible and exposed to as much sunshine as possible. As the drying takes several days, and the beans take up a large area, and as sunshine is not always guaranteed, the drying process needs careful management.

The aim is to get the water down to ~7% while not allowing the beans to be contaminated, damaged by pests, exposed to traffic fumes, or rained upon. This process is a community effort, relying on hard work and creative genius, solving problems in a way that makes sense within the unique environment of each community. But monitoring the water content is done scientifically so that the drying is well-controlled. Too fast (overheating the beans) and too slow (allowing time for molds to grow) are equally unacceptable.

The Dried Beans

So far we’ve only said “bean” without saying what it is. There’s an outer skin, or husk, which holds the bean together. Inside we have the “nibs”, individual bits of bean packed together. We now have a choice. With some difficulty we can “winnow” the beans, removing the husks, allowing us access to the nibs which we can break apart for super-efficient roasting. Or we can roast the whole bean, which is less efficient but generally agreed to be better for flavour, then more easily remove the husk and access the roasted nibs.

For our sort of cacao we tend to roast the whole beans.

Between drying and roasting, the beans need to be stored, usually in breathable sacks. Sooner or later the beans need to be sorted – removing any bad/damaged beans, and anything that’s not a bean: leaves, stones etc. Sorting also means separating smaller and larger beans from the desired average – we discuss why shortly. Modern automation can do a great job of this, but isn’t feasible for specialist beans. The sorting is hard work which simply can’t be avoided.

The sacks of beans have to be kept dry as we don’t want the beans to re-absorb moisture. They also have to be kept in a wholesome environment – beans can easily pick up unwanted aromas if they aren’t carefully managed during storage.

Roasting

The fermentation has produced a whole set of new molecules, some good, some neutral, some unpleasant. Drying has mostly reduced the water content. Roasting is what transforms the assortment of molecules into the rich set of flavours, including the transformation of proto-flavours. The classic transformation is the Maillard reaction, known to anyone who has baked a cake or a loaf of bread. The reaction is highly complex but at its heart is the combination of simple sugars (glucose, fructose) with amino acids that have been freed up (breaking down of proteins) during fermentation. We get the brown colouration and the rich, warm aromas of Maillard molecules. The roasting also gets rid of most of the lighter acids, such as acetic acid, that are not a desirable part of the final flavour profile.

You can roast cacao by putting the beans on a tray and putting the tray in an oven, but there are many downsides to this. The beans in contact with the tray experience different heat flows from those in contact with the oven air. And either you have too few beans to be efficient or so many that you now have 3 different heat zones – tray, middle and air.

Because we want each bean to be roasted identically, the removal of beans that are too small (heat up and roast too quickly) and too large (too slowly) was an important part of the pre-processing.

Fortunately, the much larger specialist coffee industry has given rise to efficient and (relatively) affordable drum roasters that, ideally, allow precise control over temperatures and times, with each bean experiencing the same average conditions as the hot drum mixes them up by rotation and the hot air distributes the heat into the beans. With sensors measuring temperatures of drum, air and beans, with computer logging of the data, with precise control over heat and air flows, the roasting team can work out how to extract the most delicious flavours, then reproduce the same flavours time after time. “Most delicious” requires at least some of the team to be trained in blind tasting – scoring the good and bad aspects of the beans from different roasting conditions without knowing, while doing the tasting, which sample is which. Blind tasting removes the subjective bias that would always favour whichever conditions the taster, for other reasons, assumed to be optimal.

This talk of computers and sensors sounds the opposite of a noble journey to a ceremonial cup. But these modern systems are greener because they are energy efficient and because they destroy fewer beans through accidental under- or over-roasting. There is nothing noble about unreliable roasting of beans that have taken so much hard work to nurture, ferment and dry.

Grinding

Removing the husk (winnowing) is unglamorous but necessary and can be done effectively with relatively simple machines. Yes, you could have lots of people removing the husks by hand, but that’s not a good use of human potential. You really need all the bits of husk removed as they would produce a grittiness in the final product. The pleasure of luxurious smooth cacao is easily undermined by a bit of grittiness.

Now we can break up the beans first into nibs (usually with a simple roller mill) start to grind them (a more complex mill) then really remove even the tiniest bits of gritty nib using a ball mill.

Milling is hard work. You can do it with a traditional stone grinder, but why would you? What we want is a reliably super-fine cacao powder ready for transformation into final blocks ready for your personal ceremony of making the drink.

Conching and Tempering

Finely-ground cacao is perfectly usable. It’s just cocoa powder and you can make a pleasant drink from it. But not a ceremonial drink. The magical transformation takes place in the conching machine. It’s a heated mixer/scraper that reduces particle sizes further, removes residual volatile acids and adds some further flavour transformations. The process works because heating melts the cocoa butter that makes up a large fraction of the cacao, so it’s a liquid transformation. Conching takes several hours, requiring a careful balance of time, temperature and mechanical energy.

You could just pour the liquid from the conching machine into a mold and let it cool as fast as possible. But the cocoa butter easily freezes into an undesirable, gritty crystalline form. This doesn’t affect the final drink, but by carefully controlling the cooling you end up with a uniform, dark, smooth, very large bar of delicious 100% cacao chocolate. If you feel like eating some, go ahead. We are so used to chocolate containing, say, 30% sugar that 100% cacao can be a challenge at first. You won’t want to eat a lot of it, but that’s the point. This is your chance to savour the full subtle flavour profile

Drinking

Time then for drinking….

Pausing the world, focussing on the cup, the aroma, the friends around you, the journey from the rainforests to your home then savouring each sip, admiring the craft that went into each step of the transformation from a bitter, inedible bean inside a husk in a pulp in a shell, into this special moment in your own journey through life.